Why Is Demand for Pet Food Kibbles Rising Rapidly?

- Shift Toward Commercial Pet Nutrition

Pet owners are increasingly moving away from home-prepared food to nutritionally balanced commercial kibbles, driven by veterinary recommendations and better product availability.

- Growth in Urban Pet Ownership

Urban households prefer ready-to-feed, hygienic, and long-shelf-life dry pet food, making kibbles the most preferred format.

- Premiumization of Pet Food

Demand is rising for:

- • High-protein dog food

- • Breed-specific and age-specific kibbles

- • Functional pet foods (digestive health, coat care, immunity)

- Expansion of Export Markets

India is emerging as a competitive manufacturing hub for pet food exports due to lower production costs and improving quality standards.

Industrial Pet Food Kibbles Manufacturing: Process Overview

Commercial pet food production requires precision-controlled, continuous processing systems to ensure product consistency, nutrition retention, and safety.

Key Manufacturing Stages

- • Raw material grinding & batching

- • Mixing and conditioning

- • Extrusion cooking (single screw or twin screw extruders)

- • Drying and moisture stabilization

- • Coating (fats, flavors, nutrients)

- • Cooling and packaging

Among these, extrusion technology plays the most critical role in determining kibble texture, expansion, density, and digestibility.

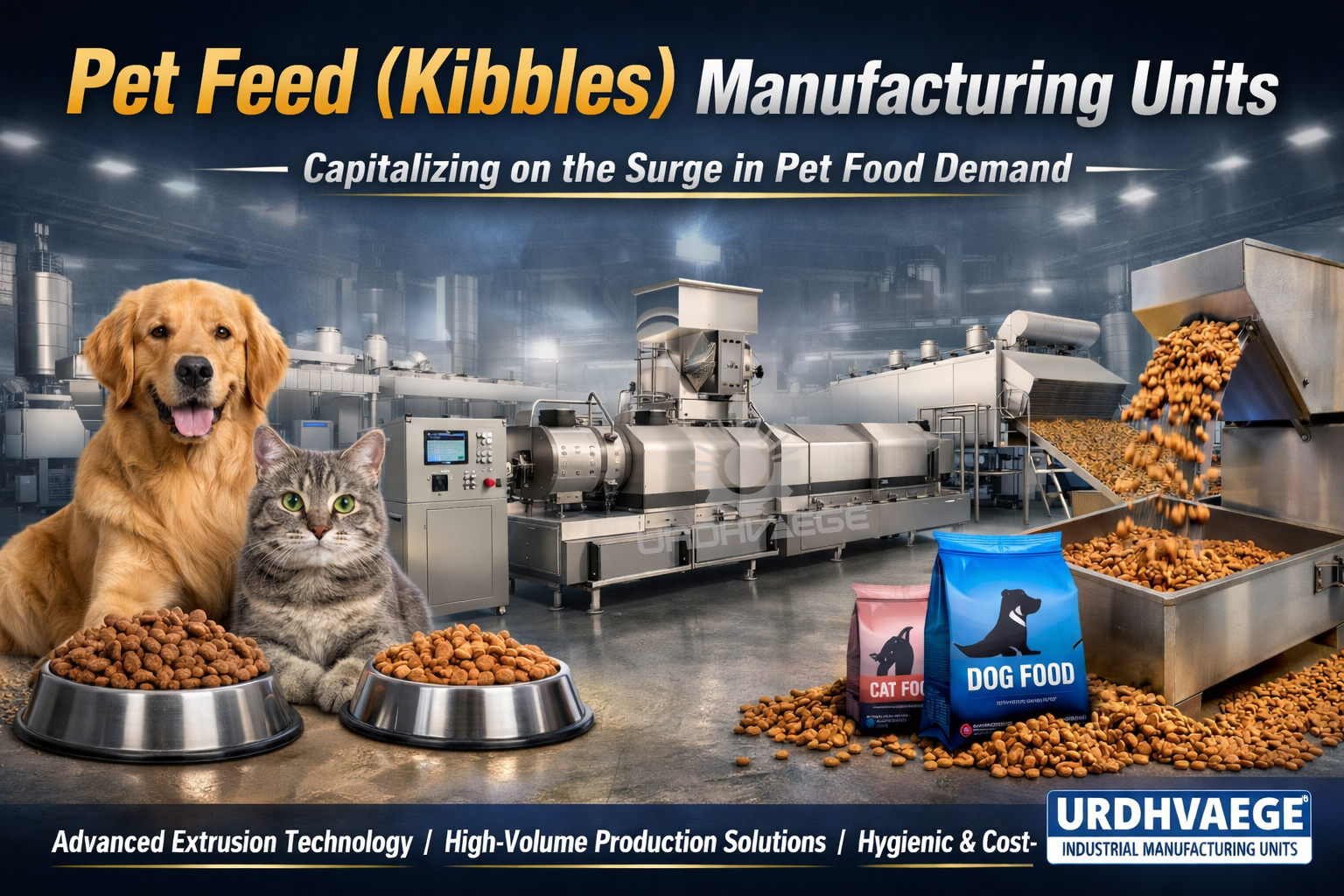

How Urdhvaege Manufacturing Units Enable High-Volume Pet Food Production

Urdhvaege designs end-to-end industrial pet food processing solutions optimized for dogs and cats dry kibbles.

- Advanced Extruder Systems

- • Single Screw Extruders for cost-effective, high-output kibble production

- • Uniform cooking, starch gelatinization, and protein denaturation

- • Adjustable die and cutter systems for multiple kibble shapes and sizes

- High-Efficiency Drying & Cooling

- • Multi-layer conveyor dryers for controlled moisture reduction

- • Consistent product quality with reduced energy consumption

- Scalable Production Capacities

- • Suitable for startup, mid-scale, and large industrial plants

- • Modular design allows future capacity expansion

- Hygienic & Food-Grade Construction

- • SS304/SS316 contact parts

- • Easy-clean designs compliant with pet food safety standards

- Cost-Effective Manufacturing

- • Optimized power consumption

- • Low maintenance and long operational life

- • Reduced production cost per kg of kibble

Market Opportunity: Why Now Is the Right Time to Invest

- • India’s pet food market is growing at double-digit CAGR

- • Rising demand from organized retail and e-commerce platforms

- • Strong potential for private-label and export-oriented production

- • Government focus on food processing and manufacturing infrastructure

Manufacturers who invest early in automated, industrial-grade machinery gain a decisive advantage in quality, scalability, and cost control.

Conclusion: Building the Future of Pet Nutrition with Urdhvaege

The surge in demand for dog and cat food kibbles represents a long-term, sustainable growth opportunity. With the right industrial manufacturing setup, producers can deliver consistent quality, meet regulatory standards, and scale rapidly.

Urdhvaege Industrial Manufacturing Units empower pet food producers with reliable extrusion, drying, and processing solutions— designed for performance, hygiene, and profitability.

Pet Food (Kibbles) for Dogs and Cats: Surge Rise in Demand

How Urdhvaege Industrial Pet Feed Manufacturing Units Are Capitalizing on This Growth

The pet food industry, particularly dry pet food (kibbles) for dogs and cats, is witnessing an unprecedented surge in demand across India and global markets. Rapid urbanization, increased pet humanization, rising disposable income, and heightened awareness of animal nutrition have transformed pet food from a niche segment into a fast-growing industrial sector.

This growth has opened significant opportunities for industrial-scale pet food manufacturing units, especially those equipped with advanced extrusion and processing technologies.

Urdhvaege India is strategically positioned to support manufacturers in capitalizing on this rising demand through robust, scalable, and cost-effective pet food production solutions.