Floating fish feed pellets are produced using extrusion technology, which allows pellets to float on water for extended periods. This enables:

Floating feed is especially suitable for species such as tilapia, pangasius, carp, catfish, and ornamental fish.

A scientifically formulated feed begins with the right raw materials:

Proper grinding, mixing, and conditioning of these ingredients is essential for pellet quality and floatability.

Raw materials are ground using hammer mills or pulverizers to achieve uniform particle size, improving digestibility and pellet binding.

Ground materials are blended in ribbon mixers or batch mixers, ensuring uniform distribution of proteins, starch, vitamins, and minerals.

The mixed feed enters the Floating Fish Feed Extruder, where:

Fresh extruded pellets are dried in multi-layer conveyor dryers to reduce moisture content, ensuring longer shelf life and stable floating behavior.

Oil and heat-sensitive nutrients are sprayed using flavour or oil coating systems, enhancing palatability and nutritional value.

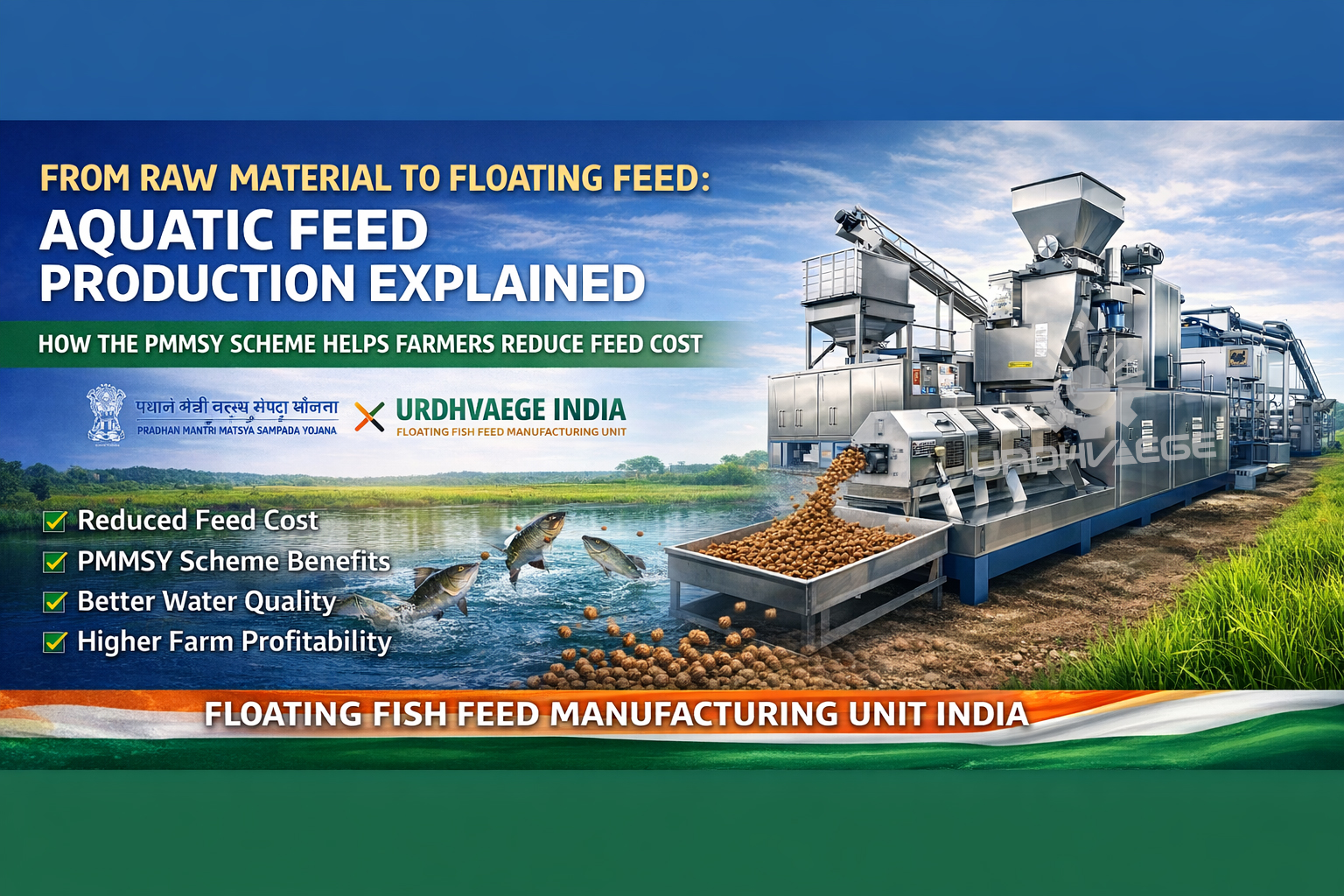

The PMMSY Scheme encourages self-sufficiency in aquaculture by supporting:

By producing feed locally, farmers can reduce feed costs by 20–35%, while maintaining consistent quality.

Why Choose Urdhvaege India?

Urdhvaege India offers end-to-end floating fish feed manufacturing plants, designed for Indian aquaculture conditions and PMMSY eligibility.

With rising feed costs and increasing demand for quality fish protein, in-house floating fish feed production is no longer optional—it is strategic.

Backed by the PMMSY Scheme and powered by Urdhvaege India’s Floating Fish Feed Manufacturing Units, farmers and entrepreneurs can achieve:

How the PMMSY Scheme Helps Farmers Reduce Feed Cost with Urdhvaege India Floating Fish Feed

Manufacturing Units

Introduction: Rising Demand for Cost-Efficient Aquatic Feed

Aquaculture has emerged as one of the fastest-growing food production sectors in India. With fish

feed accounting for 60–70% of total farming costs, the need for efficient, nutritionally balanced, and

floating fish feed has become critical.

Government initiatives such as the Pradhan Mantri Matsya Sampada Yojana (PMMSY) are accelerating investments in modern feed manufacturing, enabling farmers, cooperatives, and entrepreneurs to set up in-house floating fish feed production units.

This blog explains the complete aquatic feed production process, the technology behind floating feed, and how Urdhvaege India’s Floating Fish Feed Manufacturing Unit offers a turnkey, PMMSY- aligned solution.